Jaw Crusher For Mangenese Ore

2021-06-19T12:06:14+00:00

The Composition and Structure of Manganese Ore Jaw Crusher

2015年1月28日 Manganese ore jaw crusher is the widest used ore primary crusher Understanding the composition and structure of manganese ore jaw crusher can help us to know the working process of it and do the maintenance of the equipmentJaw Crusher The range of MACSALAB Jaw Crushers is ideal for primary crushing of samples of moderately hard materials, including coal, limestone, ore, minerals and bricks and rubble Units are sturdily constructed in Jaw Crusher Eriez – Global Leader in Separation China Manganese Ore Jaw Crusher manufacturers Select 2023 high quality Manganese Ore Jaw Crusher products in best price from certified Chinese Mining Equipment, Manganese Ore Jaw Crusher MadeinChinaManganese ore processing technology is usually divided into three stages: crushinggrindingbeneficiation The required manganese ore Manganese Ore Processing Solution Eastman Rock

Jaw Crusher an overview ScienceDirect Topics

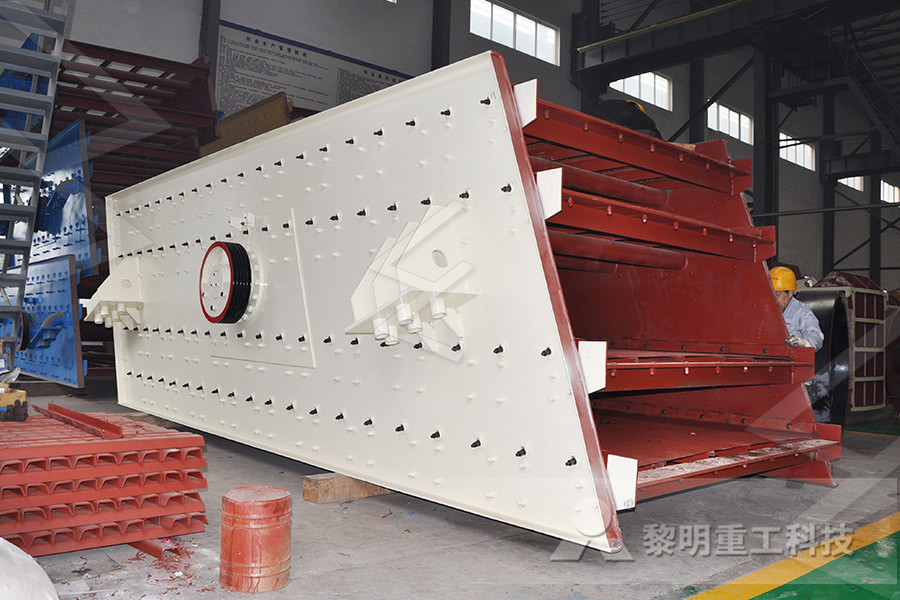

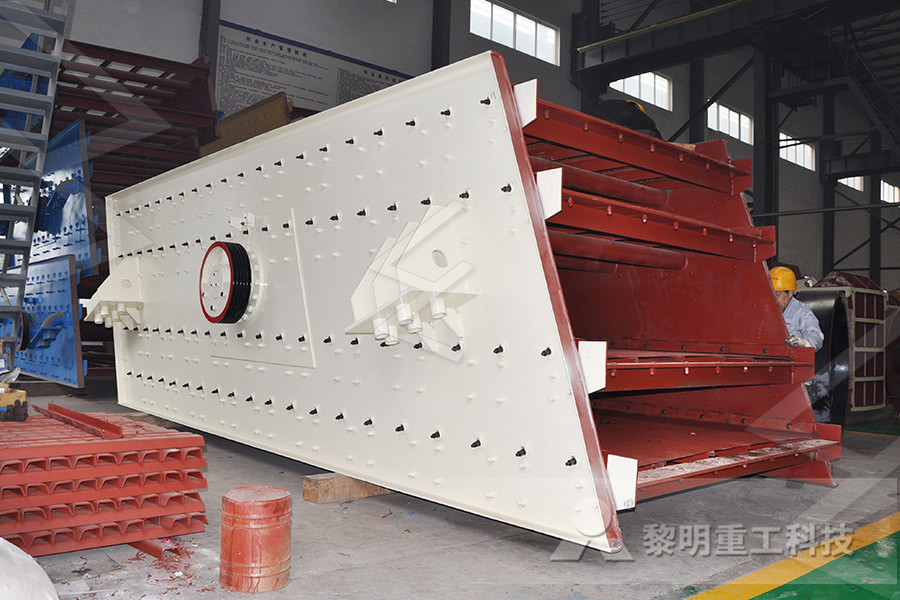

The ore is to be broken down in a jaw crusher to pass through a 115 cm screen The undersize is scalped before feeding to the jaw crusher In martempering conditions 2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, Optimisation of the swinging jaw design for a single toggle jaw crusher Jaw Crusher 2,5” x 4” accepts product feed size of 35mm, crushing it down to less than 5mm This crusher is capable of crushing volumes up to 500 Kilogram per hour of gold ore, platinum ore, iron ore, manganese ore, copper, coal Jaw crushers are always at the for front of the sample preparation chain, precrushing all hard and brittle Jaw Crushers RSE Projects2 Alluvial Rock Manganese Ore beneficiation Plant This is a setup of alluvial rock manganese ore process plant, the main equipment including: Trommel scrubber Vibrating screen Impact crusher Belt conveyor Manganese Processing Plant, Equipment Mineral

Why is a jaw crusher used to crush aluminum ore? LinkedIn

2023年3月7日 A jaw crusher is used to crush aluminum ore because it is a highly effective, costefficient and environmentally friendly way of reducing the size of aluminum ore The jaw crusher can also be used 2015年1月28日 Transmission Eccentric shaft is the main shaft of manganese ore jaw crusher, which suffers a big bend torsion force and is made of highcarbon steel The eccentric part need to be processed with finish machining and heat treatment One end of the eccentric shaft is installed with pulley, and another end is installed with flywheelThe Composition and Structure of Manganese Ore Jaw CrusherOur aftermarket manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast using varying grades of manganese steel GRADES OF MANGANESE When selecting manganese crusher liners, the liner percentage indicates the amount of manganese used in the casting Our quality cast liners come in 14%, 18%, and 22% Manganese Crusher Liners Mining Wear Parts2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] (PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

Five Common Types Of Manganese Ore Processing Solutions

2023年8月7日 The beneficiation machines for manganese ore mainly include vibrating feeders, jaw crushers, fine jaw crushers, conveyors, swing feeders, ball mills, (weak, medium, strong) magnetic separators, jig separators, ore washing machines, flotation machines, drying machines, etc The specific configuration and selection of beneficiation 2017年6月30日 In this work, two hardfacing alloys were produced based on the mass ratios of 2: 1: 1 and 7: 15: 15 for Fe: Mn: Cr by sand and open permanent mold casting processes, respectively XRD analysis (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER 2022年12月29日 Next, crush the ore to a fine powder using a jaw crusher, cone crusher, or other types of crushing equipment Transfer the crushed ore to a ball mill, and add steel balls to the ball millHow to Grind Manganese Ores Using a Ball Mill? LinkedIn2023年1月30日 Here are the steps involved: 1Exploration: Geologists locate and assess the presence of manganese ore deposits 2Mine Planning: Based on the survey results, engineers plan the mining process and How to do manganese mining LinkedIn

Manganese Ore Process Plant JXSC Mineral

The jaw crusher is for crushing the raw ore into small pieces, then to the cone crusher to get the fine sizes The vibration screen for separating the size +20mm back to the cone crusher, 020mm will to the 2023年2月7日 Jaw Crusher: Used for primary crushing of the ore to reduce its size Cone Crusher: Used for secondary crushing to further reduce the size of the ore Roll Crusher: Used to crush the ore to an How to build a manganese ore concentrator? What crushingApplication Manganese ore production line at Yunnan Material Processed: Manganese ore Output: 4000t/d Equipment Configuration: Jaw Crusher, Cone Crusher, Ball Mill Customer Evaluations: We have used Dahua equipments for many years Their product is stable with good quality and the output is high, which bring high benefits for usManganese Ore Processing Luoyang Dahua2021年11月22日 FRONT VIEW—SWING JAW FOR 36 by 25 INCH CRUSHER The heavy, twopiece corrugated manganese steel jaw plate is designed to fracture the toughest kinds of rock or ore with a minimum of power The unobstructed clearances above, between, and below the plate sections permit free flow of manganese steelHow does a Rock Crusher Work Jaw Crusher 911 Metallurgist

Our Range of Trio® Jaw Crushers Weir

Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications Within the mining industry, the Trio® CT Series jaw crusher is frequently used to process precious metals (eg gold, silver and palladium) and a wide spectrum of other minerals and oreJaw Crusher jaw Crusher is size reduction equipment Jaw Crusher is Machine which is used to crush heavy size particle into small size,also it's a primary size reducer jaw Crusher are low speed machine for coarse reduction of large particles Approx size of reduced of material from a crusher ranges from 150mm to 250mm Advantages:Ferro Manganese Plant Manganese Ore Pulverizer Jaw Crusher The range of MACSALAB Jaw Crushers is ideal for primary crushing of samples of moderately hard materials, including coal, limestone, ore, minerals and bricks and rubble Units are sturdily constructed in Cast Iron and utilise reversible hardwearing Manganese Steel jaws Features Standard motors with starters + overload protectionJaw Crusher Eriez – Global Leader in Separation TechnologiesA jaw crusher is always at the very front of the glass, materials science and environmental analysis They crush mediumhard, hard, brittle and tough materials such as ores, slag, oxide ceramics, hard coal or 12% Manganese steel reaches hardness values of over 600 HV (approx 55 HRC) stainless steel Corrosionresistant steel with an Jaw Crushers high quality and reliability from RETSCH

Why is manganese jaw used in a crusher?

2023年3月2日 Manganese jaw crushers are used in the crushing of mined ore, on industrial sites and in waste management facilities The jaws are designed to crush and grind materials quickly and efficiently 2021年8月25日 In the spirit of the partnership programme in which Sebilo Resources participates, the Finlay J1175 Jaw Crusher is owned by a partner company, XCA Mining Since its arrival on the mine in October 2019, the Finlay Crusher has been producing around 2 000 tonnes of material in two shifts spanning 16 hours Fuel burn shows the Finlay Jaw Crusher proves it's worth in manganese mining2022年6月27日 Jaw crushers are suitable for various industries, including diamonds, iron ore, nickel, uranium, copper, platinum, gold, chrome, phosphate, and manganese Why choose IMS Engineering? IMS Engineering offers a range of highquality and reliable specialist solutions for crusher plants at competitive pricesBasics Of Jaw Crushers Jaw crusher IMS EngineeringThe ore is to be broken down in a jaw crusher to pass through a 115 cm screen The undersize is scalped before feeding to the jaw crusher In martempering conditions austenitic manganese steel had better plastic flows due to a decrease in overall thermal gradient and reduction in residual stresses associated with heattreatment operationsJaw Crusher an overview ScienceDirect Topics

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated2019年7月2日 Complete equipment for manganese ore beneficiation process Mainly have the vibrating feeder, PE coarse jaw crusher, PEX fine jaw crusher, vibrating screen, bin, pendulum feeder, electrovibrating feeder, ball mill, spiral classifier, highfrequency screen, mixing tank, flotation machine, concentrator, filter press, filter separator, dryer Manganese ore processing technology and equipmentManganese ore beneficiation plant plays an important role in upgrading manganese ore Fote has many mining equipment used for manganese ore concentration for sale Processing Capacity: 10280 t/h Main Equipment: Jaw crusher, cone crusher, vibrating screen, ball mill, spiral classifier, magnetic separator, concentrator, dryer, etcManganese Ore Beneficiation Plant CM Mining Machinery2016年10月23日 DOUBLETOGGLE JAW CRUSHER The doubletoggle Missouri, as the probable inventor of the first true gyratory crusher Rutter’s orecrusher (Fig 9), patented to which was keyed a caststeel shell with inserted teeth of manganese steel The crusher weighed 225 tons and was belt driven by a 250BHP motor to give a Crushers 911 Metallurgist

Crusher an overview ScienceDirect Topics

This crusher developed by Jaques (now ® Mineral Processing Solutions) has several internal chamber configurations available depending on the abrasiveness of the ore Examples include the Rock on Rock, Rock on Anvil and Shoe and Anvil configurations (Figure 626)These units typically operate with 5 to 6 steel impellers or hammers, with a 2021年7月15日 The abrasion wear of the austenitic manganese steels with 12% Mn and 20% Mn was evaluated via jaw crusher tests The abrasive mass (ie gravel) used per test was 100 kg and 143 mm of mean sized particles The wear characterization was carried out with the evaluation of mass loss, hardness profile, worn surface roughness, and wear Abrasion wear of austenitic manganese steels via jaw crusher test2021年4月8日 Diesel Mobile Jaw Crusher Diesel mobile jaw crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide Portable Mobile Mini Stone Rock Crushing Machine Low Price Diesel Jaw 2023年2月20日 Manganese ore is typically mined in huge volumes and then processed into different forms for various industrial uses jaw crusher 400 tones per hour prices from iran Sep 13, 2023manganese ore processing LinkedIn

Manganese Ore Crusher 2018 LinkedIn

2017年10月12日 The First Stage: Crushing and Screening Large bloke of manganese ores are uniformly sent into manganese ore jaw crusher or mobile crushing station for coarse crushing through vibrating feeder颚式研磨仪应用领域 A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for online quality control of raw materials The main fields of Retsch : 产品 : 粉碎设备 : 颚式粉碎仪choice of ore that will ultimately go to the screening plant” The final manganese product is exported in two main size categories namely lumpy, which measures between minus 65mm to plus 6mm, and fines, which is smaller than 6mm When it came to choosing a mobile crusher, Sebilo Resources chose a Finlay J1175 Jaw Crusher thatFinlay Jaw Crusher proves its worth in manganese mining2023年1月12日 Manganese ore ball mill, the material out of the cone crusher needs to be ground by manganese ore ball mill, the discharge can be controlled at 01470833mm or so, the finished product is uniform in size and excellent in particle shape, and it is not easy to block the finished product rate is highManganese ore crushing and beneficiation equipment for sale

Amazon: INTSUPERMAI Jaw Crusher Mini Jaw Crusher Rock

2021年9月3日 This jaw crusher is made of manganese steel which has more hardness than carbon steel It is applicable to medium and fine crushed materials for the purposes of laboratory and production and primarily provided as environmental protection equipment for coal, electric power, mine, The large manganese ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; After the coarsely crushed manganese ore is screened by vibrating screen, it is sent to the singlecylinder hydraulic cone crusher (secondary crushing) by the belt conveyor for secondary Manganese ore crushing equipment processing technology2023年1月5日 Stone Crusher use for manganese processing There are several methods of extracting manganese from ore, including pyrometallurgical, hydrometallurgical, and electrometallurgical processesHow to extract manganese from ore? LinkedIn2023年2月3日 The type of crusher used depends on the type of ore being processed, its size, and the desired output The most commonly used crushers for iron ore processing are jaw crusher, cone crusher, hammer What type of crusher is used for iron ore? LinkedIn

Crushing Chamber Application Guide C51086:01ENG Issuu

2020年4月27日 Read Crushing Chamber Application Guide C51086:01ENG by 9 on Issuu and browse thousands of other publications on our platform Start here!2022年9月20日 This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing During the crushing process, large and nonevenly distributed impact forces occur, Optimisation of the swinging jaw design for a single toggle jaw crusher Jaw Crusher 2,5” x 4” accepts product feed size of 35mm, crushing it down to less than 5mm This crusher is capable of crushing volumes up to 500 Kilogram per hour of gold ore, platinum ore, iron ore, manganese ore, copper, coal Jaw crushers are always at the for front of the sample preparation chain, precrushing all hard and brittle Jaw Crushers RSE Projects2 Alluvial Rock Manganese Ore beneficiation Plant This is a setup of alluvial rock manganese ore process plant, the main equipment including: Trommel scrubber Vibrating screen Impact crusher Belt conveyor Manganese Processing Plant, Equipment Mineral

Why is a jaw crusher used to crush aluminum ore? LinkedIn

2023年3月7日 A jaw crusher is used to crush aluminum ore because it is a highly effective, costefficient and environmentally friendly way of reducing the size of aluminum ore The jaw crusher can also be used 2015年1月28日 Transmission Eccentric shaft is the main shaft of manganese ore jaw crusher, which suffers a big bend torsion force and is made of highcarbon steel The eccentric part need to be processed with finish machining and heat treatment One end of the eccentric shaft is installed with pulley, and another end is installed with flywheelThe Composition and Structure of Manganese Ore Jaw CrusherOur aftermarket manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast using varying grades of manganese steel GRADES OF MANGANESE When selecting manganese crusher liners, the liner percentage indicates the amount of manganese used in the casting Our quality cast liners come in 14%, 18%, and 22% Manganese Crusher Liners Mining Wear Parts2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] (PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

Five Common Types Of Manganese Ore Processing Solutions

2023年8月7日 Manganese is a type of common metal mineral in nature More than 150 types of manganese minerals have been discovered so far, but only a small portion of manganese ore with mining and utilization value, mainly including pyrolusite, psilomelane, bog manganese ore, etc Manganese has become an essential strategic mineral 2017年6月30日 In this work, two hardfacing alloys were produced based on the mass ratios of 2: 1: 1 and 7: 15: 15 for Fe: Mn: Cr by sand and open permanent mold casting processes, respectively XRD analysis (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER 2022年12月29日 Next, crush the ore to a fine powder using a jaw crusher, cone crusher, or other types of crushing equipment Transfer the crushed ore to a ball mill, and add steel balls to the ball millHow to Grind Manganese Ores Using a Ball Mill? LinkedIn